3 Comments to 'L’Artisan du Chocolat'

Subscribe to comments with RSS or TrackBack to 'L’Artisan du Chocolat'.

:: Trackbacks/Pingbacks ::

No Trackbacks/Pingbacks

Leave a Reply

You must be logged in to post a comment.

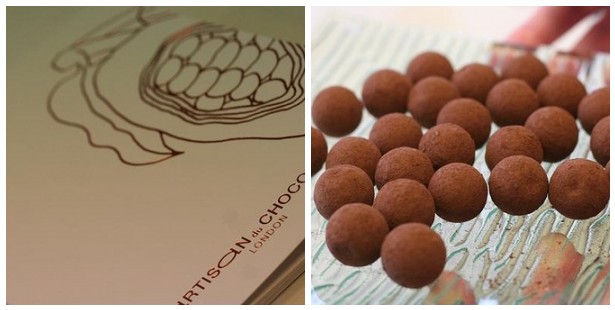

If we were going to be anywhere in Kent on a nice sunny Saturday afternoon then it would be a safe bet that nine times out of ten we would find ourselves driving down to the seaside or somewhere scenic rather than an industrial estate in Ashford, as we did a week ago. However, there was a very good reason for this otherwise crazy-sounding journey: chocolate. And not just any chocolate, but the particularly fine chocolate of L’Artisan du Chocolat.

We were there to go on a tour of their production facility / atelier and do a bit of chocolate tasting. Arriving a little early, we were led into the tasting room by Anne where we waited for a short while and browsed the catalogue while waiting for other people to arrive. Once everyone who had booked the tour had arrived (there were just under a dozen or so of us), Gerard arrived and gave us a short history of the company while telling us about the atelier tour upon which we were about to embark.

As we were entering a food production facility, we had to dress for the part. Which meant a hair net, overcoat and shoe covers. All very attractive and stylish – they’ll be on the catwalks of the world next year without a doubt.

The first area that we entered was, appropriately enough, the area that ingredients first enter when they arrive. Shelves were stacked high with dry ingredients ranging from the usual bulk sugar, milk powder, etc, to more interesting additions such as rose petals and dried cherries. Organic ingredients are stored to one side. The large walk-in fridge contains ingredients such as cream that needs to be kept cold. Particularly interesting is the small separate fridge compartment where the Marc de Champagne for Champagne truffles is stored, along with Chapel Down English sparkling wine for the truffles that are made from it. When ingredients arrive, they are all inspected and carefully checked for quality and contamination before being allowed into the facility, where they are each marked with a lot number for full traceability.

All very interesting, but all very warehouse. Into a kitchen area next, and we are getting closer to the heart of the operation. Gerard starts opening cupboards and producing strange and wonderful ingredients to show to us. The first was raw sea salt imported from France. We tasted a few crystals and it really did taste of the sea rather than just salt; it includes sea minerals and flavours that just don’t exist in refined salt. This is of course the salt that goes into their acclaimed salted liquid caramels. Next in the curious list of ingredients were sun dried limes. They look like tiny melons and when broken open they reveal blackened remnants of lime which doesn’t look very appetising but tastes really interesting, with a fermented citric acidity coming through and lasting on the tongue for a long time. Also black cardamom, which is larger than the usual green cardamom used in cooking and smells really smoky, almost like a peaty whisky.

From there into the production facility itself. Walking through the door we were met with three tables covered in jasmine scented ganache resting before being used as interiors for truffles. Gerard took us to a table in the centre of the room and started opening containers, taking out some cocoa butter and cocoa powder. Most companies use these two ingredients, he explains, to make their chocolate – a large company will extract them both from the cocoa beans and sell them in bulk for other people to make their chocolate from. At L’Artisan du Chocolat, they use whole cocoa beans themselves, so don’t need to use the separate ingredients. It is interesting to have a look at them though; especially the cocoa butter which is a very strange substance. It is a very stable fat, and tasting it, it doesn’t taste like a lot and has a curiously waxy mouthfeel due to its melting point being slightly under body temperature.

These properties of cocoa butter make it ideal for use in cosmetics and in fact it has become the most valuable component of the cocoa bean. This led to the chocolate industry discovering a way of making chocolate cheaper: extract the cocoa butter, sell it off to the cosmetics industry and then replace its role in chocolate-making with cheaper (and unfortunately less tasty) vegetable fats. No such dubious practices here at L’Artisan du Chocolat though; in fact as I mentioned above, they use the whole cocoa bean rather than separating it into cocoa powder and cocoa butter anyway.

Next up, we taste some cocoa mass which is what you get if you press the cocoa beans yourself and don’t separate them into cocoa and cocoa powder. It is unsweetened and comes across as being bitter, but you can certainly taste the fact that it would turn into chocolate with a bit of refinement and sugar. That was cocoa mass from one particular variety of cocoa plant grown in Brazil, which is what gives it that particular taste. Then we tasted another, which was from a different variety grown in Java. The Brazilian one was coarsely ground and also had a smoky flavour to it, whereas the Javan one was more finely ground and tasted a little sweeter with fruity notes to it.

From this we went on to taste chocolate bars made from refined chocolate from various sources.

Gerard explained how chocolate is conched, which means that it is mixed over a long period of time to soften it and remove the bitter flavours without having to add anything extra to it. These bars actually tasted like chocolate, but between the four of them there was still a range of flavours, textures and characters depending on where the cocoa beans had been grown. It does give you an insight into the variations that exist in natural products; in the world of wine we celebrate the differences between different varieties grown in different regions of the world, but with chocolate we usually end up buying over-processed, mass-produced chocolate from large corporations that lose the individuality of the chocolate itself. Of course when you are running an artisan operation like this, you can keep each of these individual chocolate characters and pair them with different fillings and flavourings that match them well rather than using homogenised, mass-produced chocolate.

Next, into a room containing a number of machines and moulds. Chocolate needs to be tempered before being used in moulds, etc, which means bringing it down to one degree above its solidification temperature slowly to prevent the fat separating from the rest of it. Then it can be used in moulds to create all manner of shapes and creations.

While Gerard was explaining all of this to us and showing us various moulds including hearts and a rather large chicken, Anne was at the other end of the room, patiently coating hundreds of dried cherries in chocolate. These would then go down a conveyor belt to dry and then join their friends in a box. After that, a quick visit to the walk-in fridge and freezer, then past all the packaging waiting to be filled with delicious chocolate creations:

And then back into the room in which we had started, and time to taste some of these creations. We tasted a number of different chocolate truffles from their range, including the brilliant salted liquid caramels. Gerard ran us quickly through a history of the company – they have been in operation for 10 years, and three years ago they moved to this larger facility to help them increase their production and provide more scope for developing new products. When they started out, he was working in a single room producing wonderfully crafted chocolates – Gordon Ramsay started serving his chocolates in 1999 and he started making tobacco chocolates for Heston Blumenthal’s Fat Duck in 2000. Now that others have started copying their famous salted caramels, they have been coming out with a few new flavoured twists on the theme to keep ahead of the game. They now have a few shops across London – in Chelsea, Notting Hill and in Selfridge’s too.

I was really impressed by the tour and the in-depth explanations that Gerard gave us about every step of the production process. His passion for and knowledge about everything chocolate-related shows through at every point and although they have moved into a larger production facility and employ staff there,

everything still has the impression of being hand made, with a heavy emphasis on using fresh ingredients and experimentation.

Tours cost £35 per person (we didn’t pay for ours though) and are on certain Saturdays

Web site: http://www.artisanduchocolat.com

Chocolate tour and tasting details

This was very interesting for sure! Sounds like a great and educational tour. It is too bad that the artisan chocolate shoppes are going the way of just about everything else. Hopefully we will begin to realize we are headed down the wrong path and make a U-Turn!

.-= GrilledShane´s last blog ..Cheese Tasting: Parrano, Roomkaas, Mahon & Tomme de Savoie =-.

Sounds like a good tour. I was eyeing this up on their website around the time we attended their store opening and thinking it might make a good gift for a chocoholic friend.

Do you know if tours are always conducted by Gerard or whether they are sometimes taken by another member of his team? Don’t worry if not sure, can check with them directly.

.-= Kavey´s last blog ..Pete’s "Courgette ‘Saka" =-.

I think Artisan manage to find a good balance, Shane. They have had to move to a larger site and use some machinery to cope with demand but the majority of the process is still hand-made.

I think Gerard does all the tours, Kavey, I don’t know for sure though.